Green LiDAR for Stream Gauging

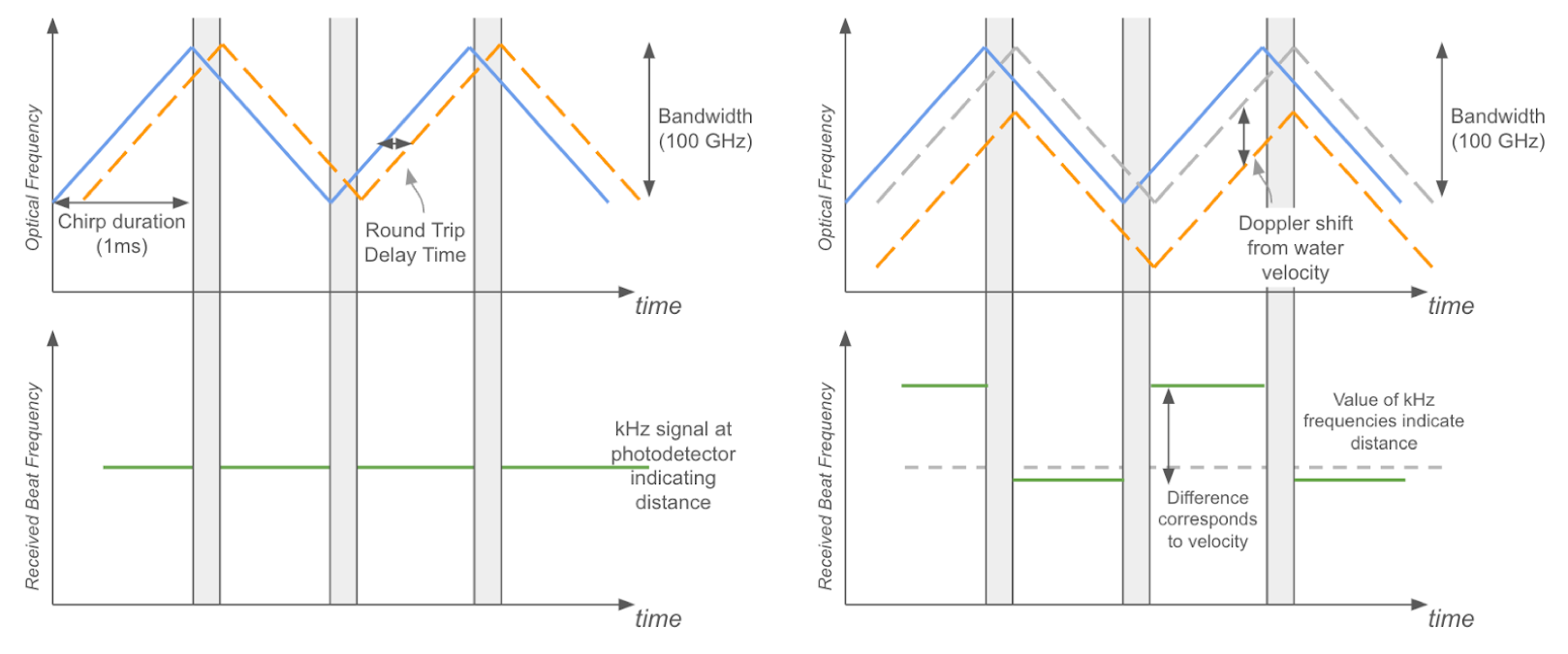

To measure the volumetric flow rate of a river, one needs to know the distance to the bottom surface, the top surface, and the velocity of the water. We are developing a FMCW LiDAR that can accomplish all three of these tasks in a single device, making an integrated non-contact solution for stream gauging.

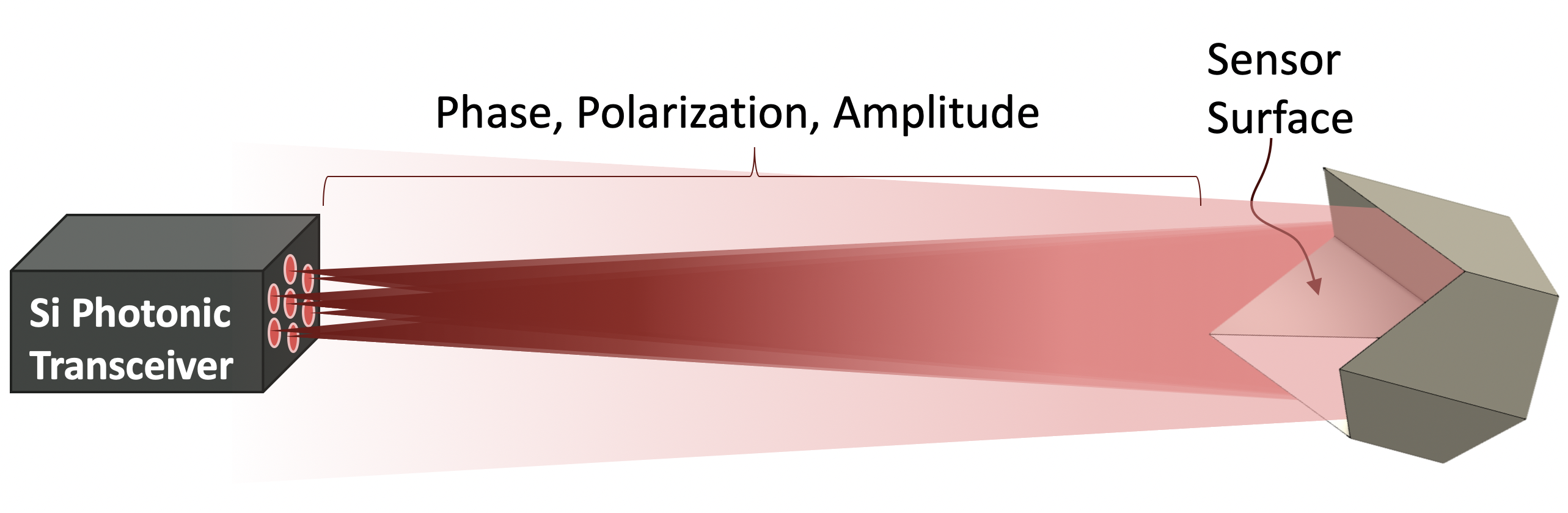

Free-Space Retroreflective Sensor Platform

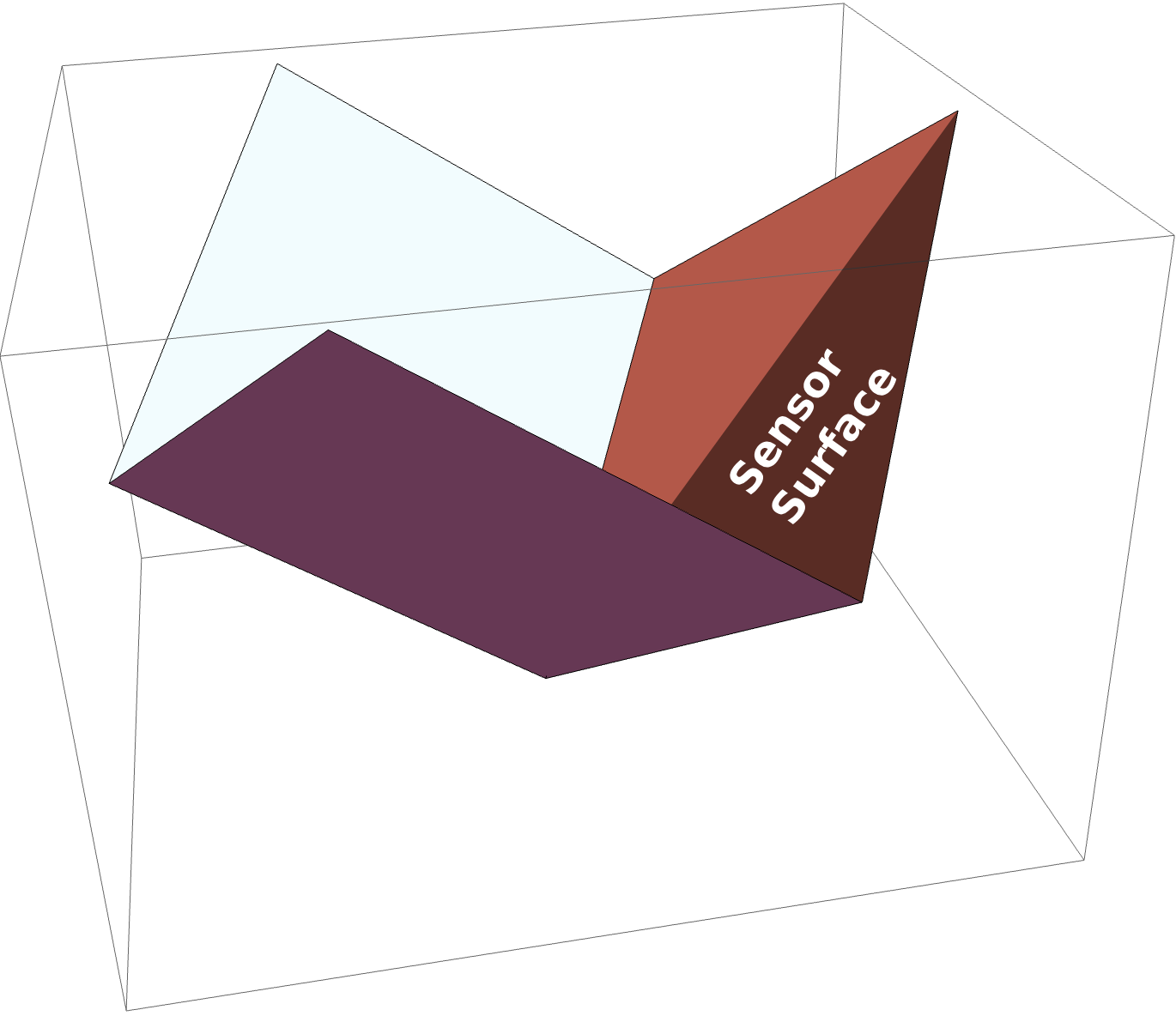

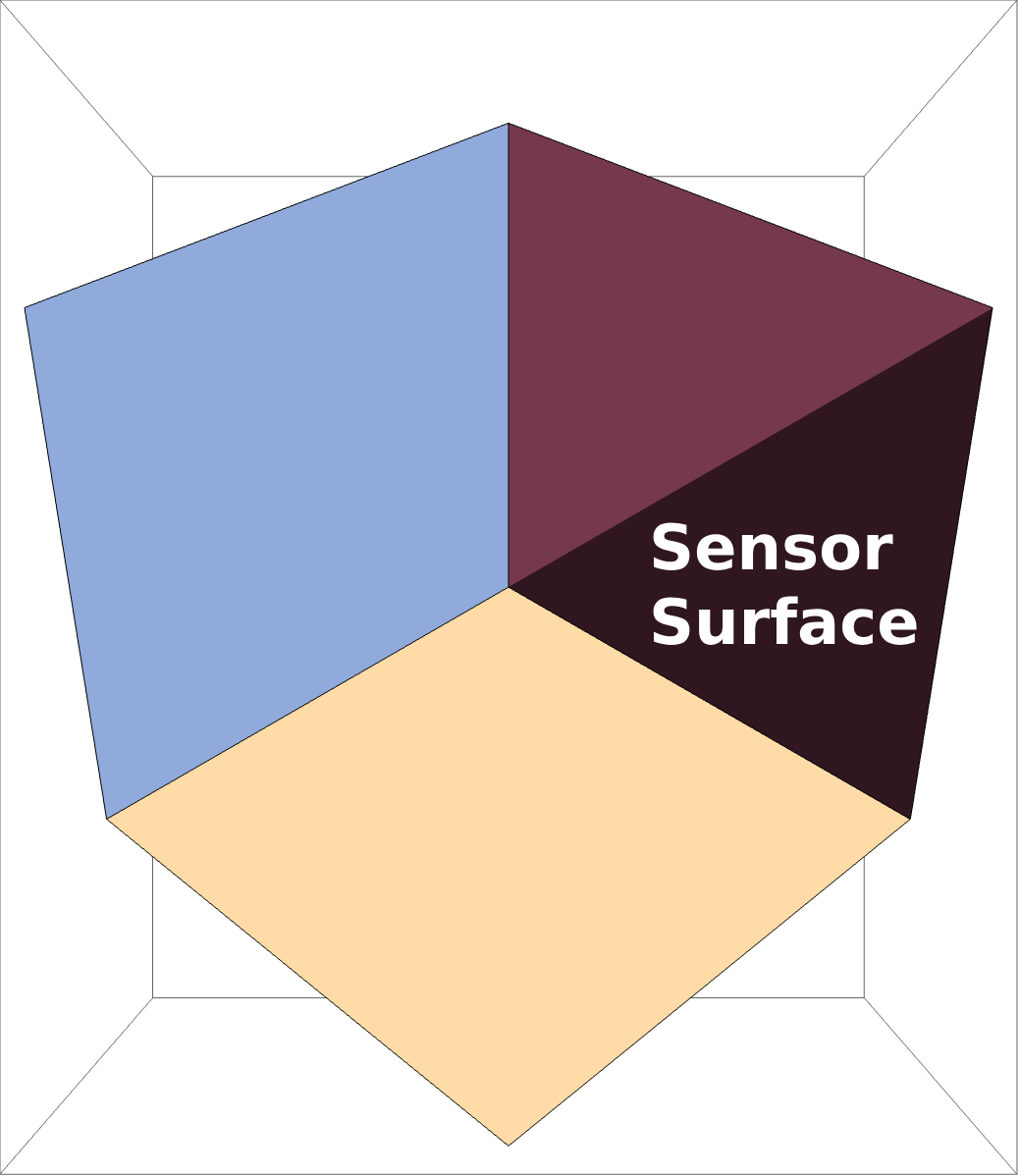

Whether the thin film is sensitive to methane or temperature, we are able to distinguish change in phase or amplitude of the reflected light from the sensor surface from hundreds of meters, allowing us to utilize a single transceiver to read out many devices. In this project we are hoping to change the way that environmental scientists think about the problems that they are trying to sense by creating a system that the user can arbitrarily select the temporal and spatial scale with a truly scalable sensor network.

We are engineering diffraction patterns for corner cubes with embedded thin film sensors to make scalable distributed optical sensors that can be used reference-free.

Resonant Scanner based LiDAR system

What is a resonant scanner and why it's good?

A MEMS mirror scanner has a compact form factor, low power consumption, and enables fast laser beam scanning. By operating the MEMS mirror at resonance, the scanning range can be enlarged by 10~100x in each dimension compared to an off-resonance scanning mode.

What can we do with the resonant scanner?

Despite the advantages, current resonant MEMS mirrors have several practical drawbacks, including non-optimal, inflexible scanning patterns, inherent phase uncertainty, and insufficient data-processing software. Therefore, a co-design on the system is required, from optical MEMS device to computer vision algorithms.

What is the impact?

Our ultimate goal is a LiDAR system based on resonant MEMS scanner(s), that operates at ~100Hz frame rate, which is at least 3-10 times faster than the current LiDARs. Such an increase in speed will significantly improve user experience and safety in broad applications, including robotics, autonomous driving, and AR/VR.

The current stage of research

We are actively working in this direction. At the current stage, we've designed different components of the system and we are trying to integrate them. Please refer to the publication page for more details.

Grating Light Valve based LiDAR system

What is so special about our LIDAR technique?

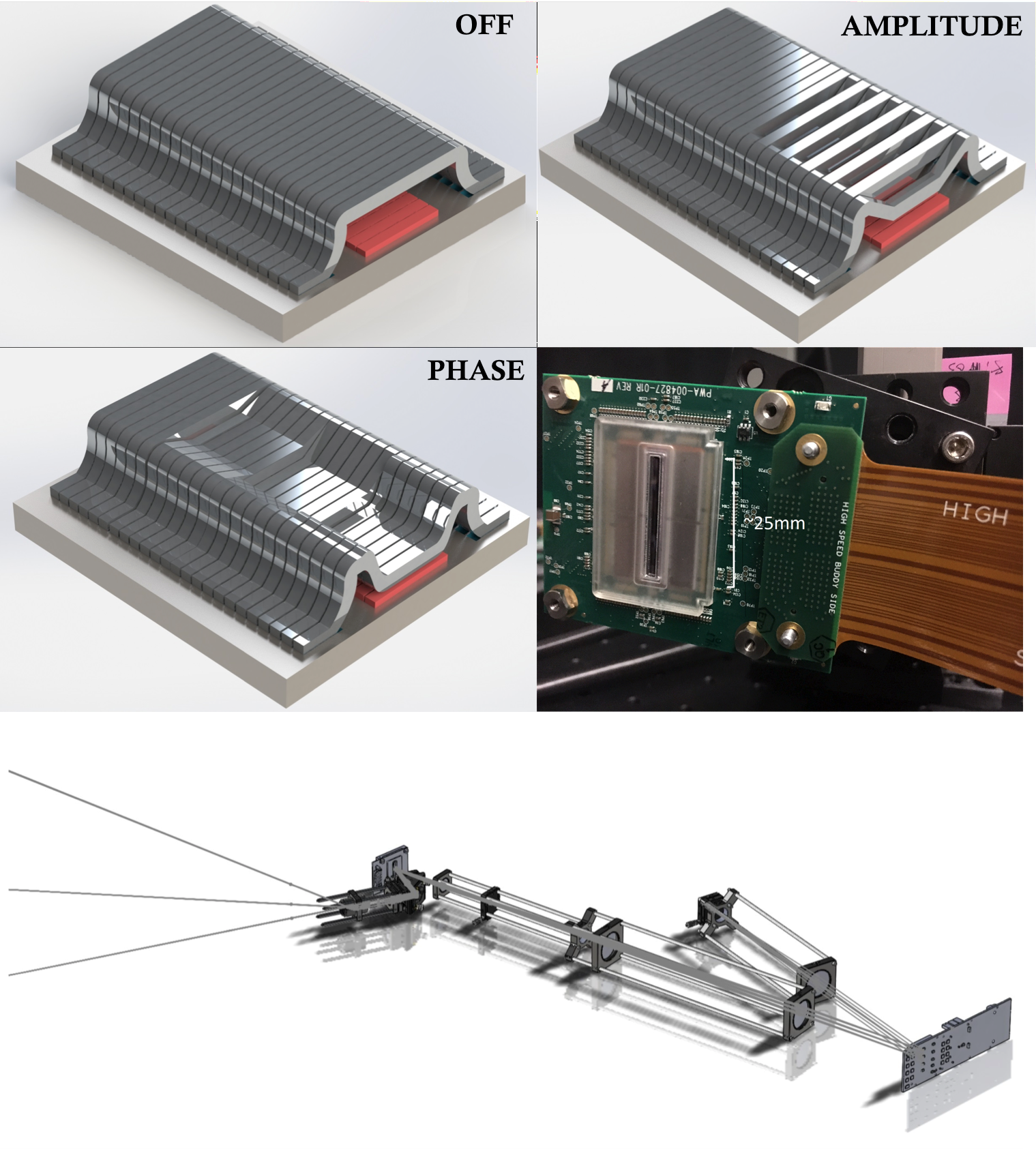

The LIDAR project uses the MEMS ribbon technology (GLV or Grating Light Valve) first developed by Solgaard during his PhD for far field beam scanning for remote sensing.

What is a GLV and why do we use it?

We use the GLV as a phased array. Small voltages control silicon ribbons that act as a diffraction grating for the pulsed laser light.

What can we do with the GLV?

Each ribbon can be actuated down independently, enabling very high speed (> 100kHz) random access phased array operation. Single access deflection has already been demonstrated.

Why is this useful?

Using a MEMS phase array allows for robustness, reliability, large scan angles, and high speed at relatively little cost. This is incredibly useful for autonomous control applications.