SON Fabrication Process for the Pressure Sensor

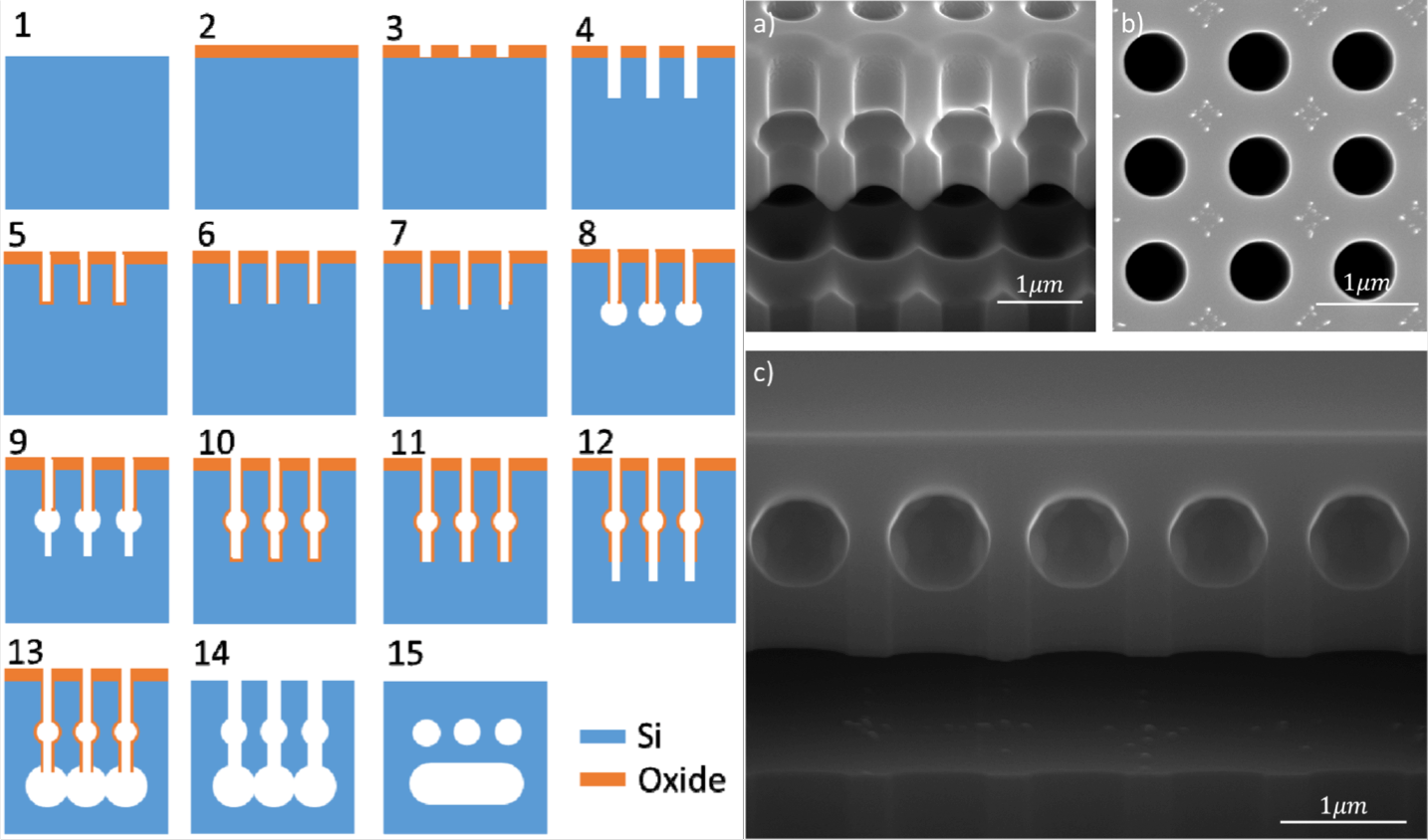

Left: SON Fabrication Process

The important part of the fabrication process for SON calls for two cycles of (i) directional reactive ion etch (RIE), (ii) low-temperature oxide deposition, (iii) directional RIE for oxide removal at bottom of cylindrical holes, (iv) isotropic etch to create spherical holes. The second cycle calls for larger holes to allow for a cavity upon hydrogen annealing in the final step.

Right: SEM Images of Process

(a) Imaging at tile 13 of SON process (before hydrogen annealing). (b) Another view of the pre-hydrogen annealing step. (c) Final result at tile 15 (after hydrogen annealing). From this process, we have created a Fabry-Perot cavity with a length (and therefore, the reflectivity spectrum) adjusted by a movable diaphragm sensitive to external pressure.

Pressure Sensor Experiments and Results

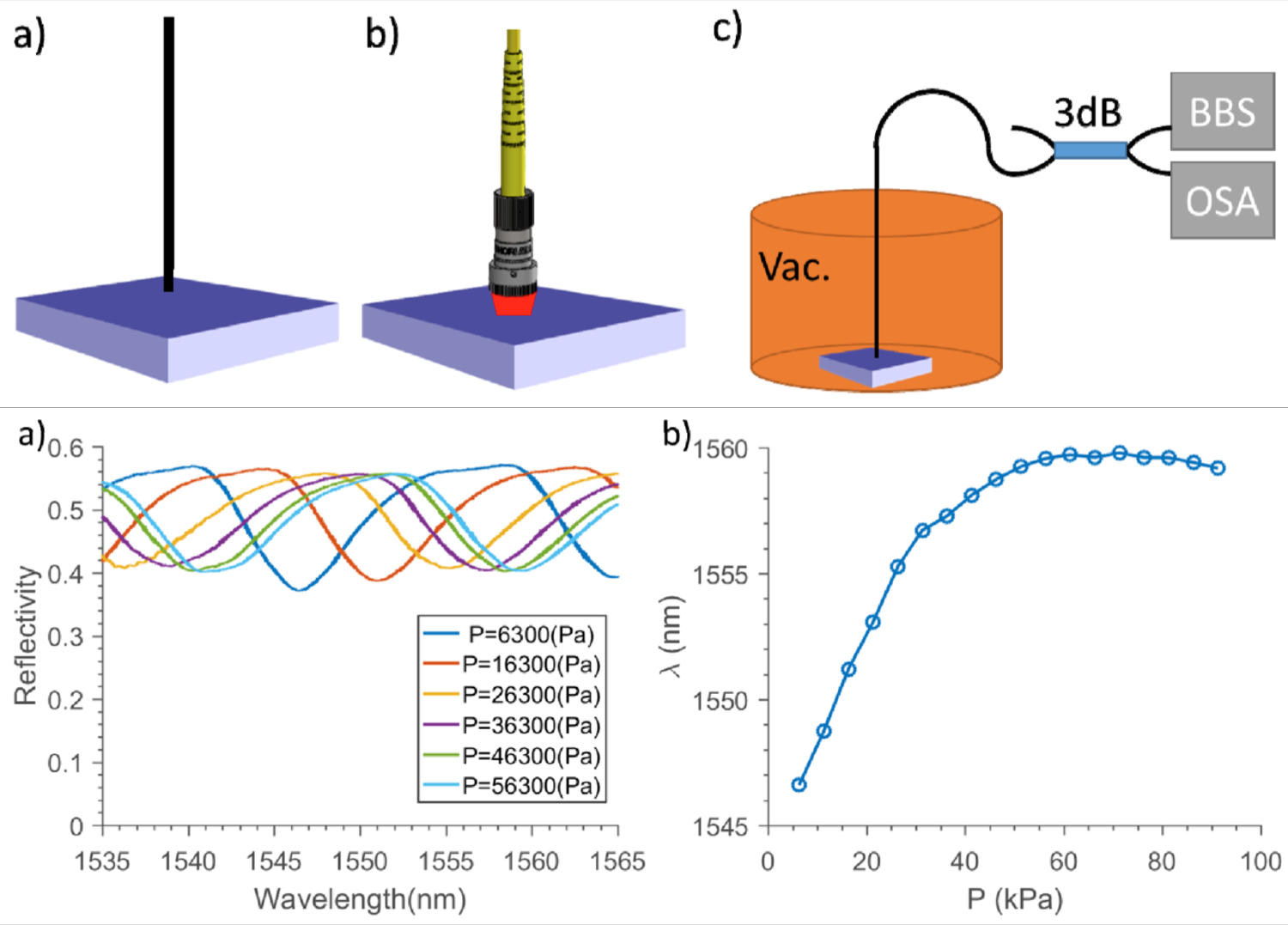

Top: Experimental Setup

The pressure sensor consists of an optical fiber (gold coated in (a) and AR coated in (b)) collimated into to the fabricated Fabry-Perot cavity placed in a vacuum chamber. A 3dB coupler is couples the light sent from the broadband source (BBS) and into the light measured by the optical spectrum analyzer (OSA).

Bottom: Gold Coated Fiber Results

(Left) The reflectivity spectrum at different pressures. (Right) The minimum reflectivity wavelength in the Fabry Perot cavity plotted at different pressures. Note the higher resolution of pressure at lower pressures (~ 0.48nm/kPa).